Our Approach

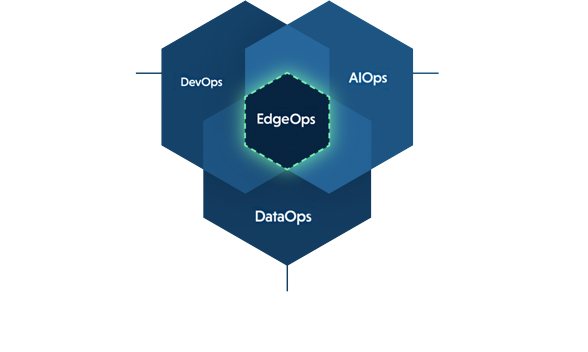

Adapdix EdgeOps is a data-driven analytics platform suite that integrates ML/AI at the customer site. An EdgeOps solution incorporating the DevOps, DataOps and AIOps methodologies presents an opportunity for customers to strengthen, scale, and automate routine business practices and streamline interactions between functional groups to help organizations quickly implement solutions to difficulties they face.

What Does Adapdix EdgeOps Bring?

EdgeOps Puts the Customer First:

- Foster rapid application development and integration

- Shorten the lifecycle of model development and deployment

- Automate data analytics to improve quality and reduce cycle time

- Integrate microservices data for building new ML/AI applications

- Enable data scientist and data engineering teams to seamlessly manage data

- Facilitate customer updates and platform scaling

- Manage multiple observability between different reporting formats

- Incorporate specialized 3rd party AI/ML models

Industry Solutions

An edge-to-cloud based solution managed in the EdgeOps platform offers several advantages by reducing non-critical data processing from the cloud using advanced analytics at the edge, which are much nearer to the source of data.

An edge learning solution greatly improves scalability of systems while optimizing network efficiency reducing the amount of data sent to the cloud especially when applications such as AI and machine learning are involved.

Semiconductor

Manufacturing

Develop solutions to increase system uptimes, increase yields and revenue, and reduce cost of ownership of increasingly complex equipment and systems. Seamlessly integrate and monitor your production operations in real-time. Reduce spare parts costs.

High-Tech

and Electronics

Automation & Assembly

Gain insight into the complexities of high-tech production and operations management. Leverage your existing machine and process data to manage costs and minimize time-to-value – all while optimizing logistics and maximizing ROI. Use data isolated inside machines and processes to quickly identify production inefficiencies and pinpoint potential safety, production, or environmental issues.

Energy

Deploy solution to optimize exploration and production processes. Manage distributed substation and transmission equipment to predict performance degradation. Avoid critical failures in electric meters or field equipment conditions.